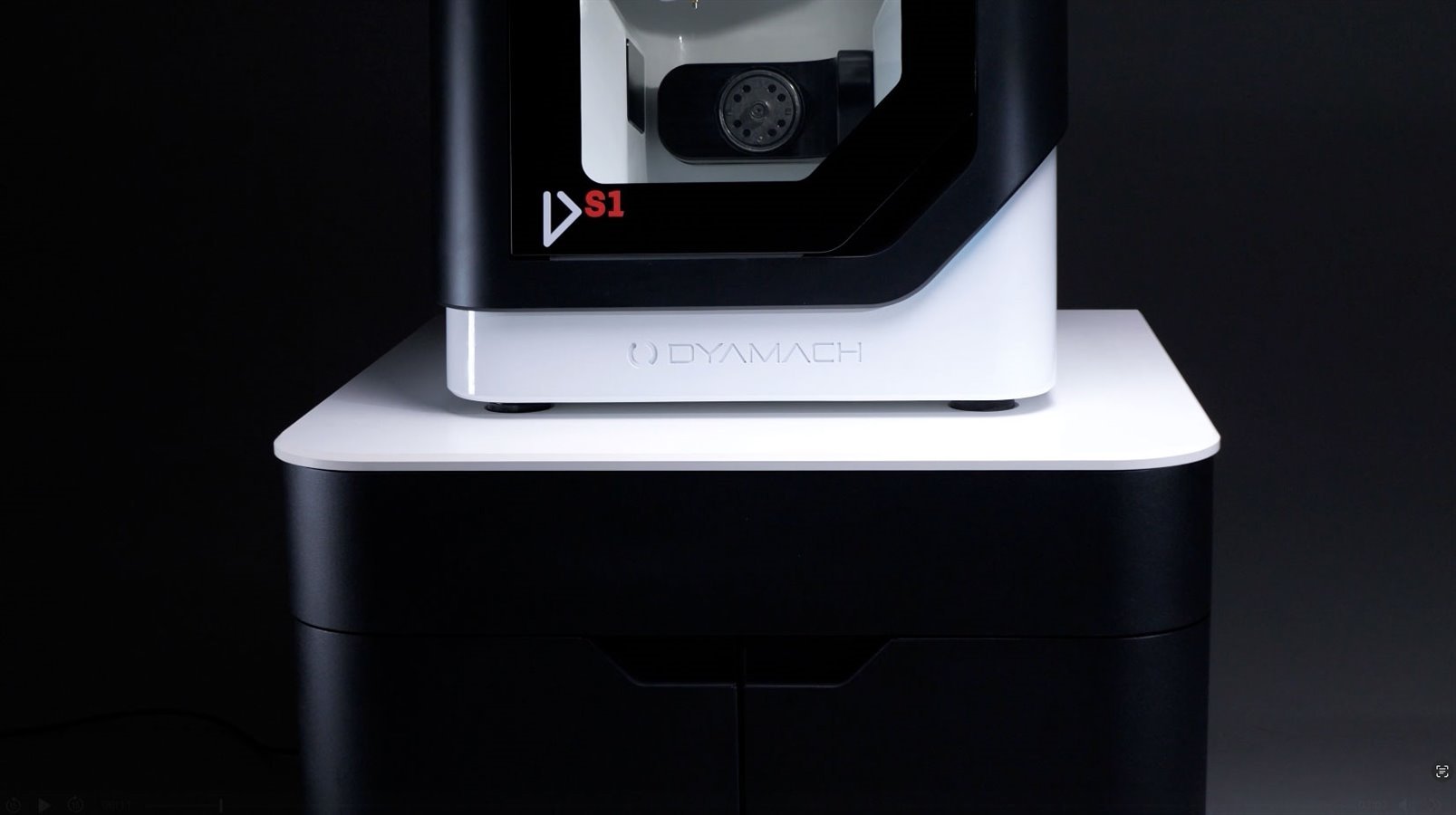

DS1 Plus

The compactness of DS1 in wet machining processes.

.png)

The compact 5-axis milling machine for dry and wet machining, ideal for making temporary and definitive elements.

A new design for a standard machine. Agile and precise, characterised by exceptional accessibility. DS1 PLUS is our response to the need to perform machining operations on materials such as fibreglass-ceramics and SLM secondary machining with proven simplicity and performance. The machine is characterised by its extreme robustness, a hallmark of all our products. The new Dyamach NC greatly simplifies the user experience, thanks to its clarity and usability.

.png)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.png)

.png)